Choosing a finish for my Hurricane resistant Windows & Doors

More and more, when renovating an older property or building a new home, people are choosing Hurricane rated Windows and Doors, and the reason for this is not only because of the safety factor involved, but also because of the energy efficiency and sound attenuation that these units provide to the interior environment of the residences where they are placed.

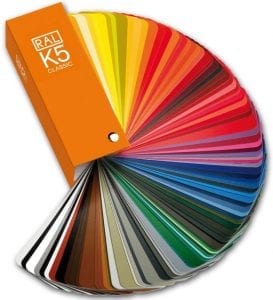

The most common materials that Hurricane rated Windows and Doors are built from are wood, vinyl and aluminum, and it is often thought that there is not much flexibility in terms of finishes and colors. The great news is that this is no longer true! You can choose from a large variety of RAL colors which can satisfy the most demanding tastes and selections.

The most common materials that Hurricane rated Windows and Doors are built from are wood, vinyl and aluminum, and it is often thought that there is not much flexibility in terms of finishes and colors. The great news is that this is no longer true! You can choose from a large variety of RAL colors which can satisfy the most demanding tastes and selections.

It is also true that, according to the material selected for your Windows and Doors, some finishes may be available at a lower price range. For example, when you buy Aluminum Products, white, bronze and clear anodized are the standard finishes; therefore the Window or Door would cost you 30% less if you buy the standard instead of the custom color. But when you balance the cost against the number of years that you will be having that Window or Door at your house – not less than 15 years – then that 30% seems worth it. Also, customizing the paint may mean

increasing the resistance to the weather as you may request the use of more coats of paint or a paint with coastal resistance properties which mean adding more years to the life of the products.

When dealing with Metal Products, not only Aluminum but Bronze or Stainless Steel, the customization of the finish could involve a change in the method of painting the units which could mean optimizing the resistance of the finish as for example powder coating.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically

Powder coating is a type of coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically

and is then cured under heat to allow it to flow and form a “skin”.

There are options for each material and we can definitely guide you through the selection process. Let us talk!